Features

Chemicals

Insects

Patternator measures sprayer efficiency

February 11, 2010 By Hugh McElhone

One of the first tasks Dr. Jason S.T. Deveau wanted to undertake as the application technology specialist for the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), based in Simcoe, Ont., was to develop a simple method for showing growers how to properly use spray nozzles to reduce drift, improve crop protection, and save money.

One of the first tasks Dr. Jason S.T. Deveau wanted to undertake as the application technology specialist for the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), based in Simcoe, Ont., was to develop a simple method for showing growers how to properly use spray nozzles to reduce drift, improve crop protection, and save money.

|

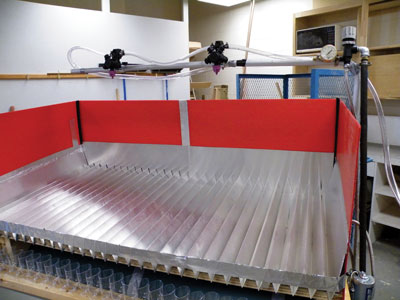

| Dr. Jason S.T. Deveau, application technology specialist for the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), worked with students at Mohawk College in Brantford, Ont. to construct a portable spray table to show how to set and operate nozzles. (Contributed photos) Advertisement

|

From this arose his idea for a novel construction project: a portable spray table to show how to set and operate nozzles. While the idea of a spray table is not new, he says the design and the means of construction are. “I wanted it to be wet, interactive and very revealing, but I needed help to make it happen.”

With this project in mind, Dr. Deveau contacted Mohawk College in Brantford, Ont., and asked Richard Dupp if his students would be interested in co-designing and building the device. “I didn’t know Richard at the time but he was eager to take this on, he and his co-op students saw it as an important real-world project and a great learning opportunity,” said Dr. Deveau.

Work was still ongoing at the time of this interview but the prototype was already constructed and the completed patternator is on-track to make its debut at the 2010 Ontario Fruit and Vegetable Conference. As well, Dupp has been documenting the entire process from the development stage to final product, which could prove valuable when submitting future OMAFRA and Mohawk projects for funding consideration.

“Colleges are truly an untapped resource in this province,” says Dr. Deveau. “Co-operative students tend to worry less about the theoretical aspects of the job and concentrate more on its usefulness and practical applications.” He hopes more researchers will consider the college resource in the future.

Explaining how the patternator works, Dr. Deveau said the table is essentially a two-nozzle boom suspended over an aluminum deck that has been folded into a series of V-shaped channels. The channels divide the spray pattern, and slope just enough to guide the spray water to the front of the table and into a series of collection vials. Inside each vial is a float to indicate the water level and demonstrate the spray pattern to viewers.

By changing variables such as pressure, nozzle spacing and nozzle quality, the patternator can demonstrate how to best set-up and calibrate a sprayer.

Water is re-circulated from a 40-gallon reservoir that serves double duty as water supply and storage container for the equipment when not in use.

The water is pumped to the spray tips by a Hypro pump, rated for 90 psi. This is sufficient pressure for testing a variety of nozzles, including air-induction. Once the demonstration is complete, the pump is turned off and a lever pulled to invert the vials fully. The water then spills into a trough that returns it to the reservoir for re-use.

To simulate wind and spray drift, Dr. Deveau uses two variable-speed portable fans that can provide velocities of 12 to 20 km per hour. Wind velocity is measured using a hand-held Kestrel weather meter that measures barometric pressure, temperature and humidity, as well as wind speed. Plexiglas sides help to contain water splatter and lateral drift.

“Once it’s set up, the patternator will demonstrate how nozzles work and the patterns they spray,” says Dr. Deveau. It will also show any pattern loss from wear and tear on old nozzles, as indicated by the water level in each vial.

“The sprayer industry has been using similar equipment for years but they generally need a permanent structure to house them. Once disassembled, this version will fit neatly in the trunk of a car, and it should be as effective as the larger versions,” says Dr. Deveau.

Being portable, the patternator can be set up at agricultural events anywhere in the province, or when battery-operated, moved to a farmer’s field for a group demonstration. “It’s very effective and will quickly show how well nozzles are performing,” says Dr. Deveau.

“Growers tend to be reluctant to change their nozzles because they did a good job last year, and they seem to be doing a good job this year. Unfortunately, many are not aware of the wear, pattern change and product loss. And it happens to all nozzles, even the ceramics,” he noted.

Using the patternator, Dr. Deveau’s team can test a grower’s nozzles and determine if they are truly delivering the product to the target. If worn by five per cent, then there is a five per cent loss.

“This may not sound like much,” he explained, “but if it costs you $1,300 to spray your crop once, and you spray it five times, that five per cent loss amounts to about $325. It adds up fast and happens more often than people realize,” he said.

Replacing all sprayer tips on a small orchard sprayer would cost roughly $150, and Dr. Deveau would like to see all growers change them annually. “The simplest things are generally the easiest to change and doing this would improve crop protection and still be cost effective.”

“The patternator is a great tool to get information across to growers in a fun, interactive, yet meaningful way,” says Dr. Deveau.

Print this page