Features

Production

Research

Nova Scotia fruit tour highlights replanting methods

Nova Scotia fruit tour highlights replanting methods

November 7, 2008 By Dan Woolley

The Nova Scotia Fruit Growers Association’s 2008 orchard tour, held in late August, helped to illustrate how Annapolis Valley apple growers are adapting new varieties to Atlantic growing conditions.

|

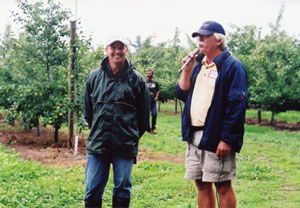

| Brian Boates (left) and Bill Craig, an Agra Point tree specialist, discuss the organic orchard plantings at Boates Farm near Woodville, N.S. Photo by Dan Woolley |

|

| Andrew Parker farms with his wife, Gail, near Woodville, N.S. They have been busy grafting their older plantings over to Honeycrisp. Photo by Dan Woolley |

|

| A smiling Waldo Walsh (left) listens as Bill Craig, an Agra Point tree specialist, discusses Waldo’s pruning and composting program. Photo by Dan Woolley |

|

| Scotian Gold grower representative Larry Lutz explains the extensive replanting program undertaken by former B.C. grower Al Fisher at Annapolis Gold Orchards. Photo by Dan Woolley |

The Nova Scotia Fruit Growers Association’s 2008 orchard tour, held in late August, helped to illustrate how Annapolis Valley apple growers are adapting new varieties to Atlantic growing conditions.

Each of the orchards visited during the annual tour featured an active program for grafting or replanting new, high-value cultivars.

Boates Farm

In Woodville, N.S., Brian Boates of Boates Farm began organically growing apples in 1994. Today, 80 per cent of his blocks are producing Honeycrisp with the remaining 20 per cent planted to Pacific Gala.

When he planted his first block of Honeycrisp, Boates chose land that had lain fallow for 20 years. He ripped the soil two feet deep and then applied composted beef manure. He trellised using metal conduit since, as an organic grower, he cannot use treated wood.

This season, Boates added some additional beef manure as compost around his trees and knocked down the weeds in the orchard rows using a grass cutter in late July. He also composts orchard rows with straw (four bales per row, 16 bales per hectare) to help control the weeds.

Boates says his biggest problem to date has been with aphids. He uses Safers Insecticidal Soap (Trounce) as his organic control. “It knocked them down, but it doesn’t eliminate them,” he admits.

Next year, he plans to get professional advice as to the best time to apply the control. For scab control, Boates uses copper sulphate, sulphur and lime/sulphur.

Parker farm

At Gail and Andrew Parker’s nearby operation, more than 10 acres have been grafted from Macintosh, Idared, Viking and Spys, to mainly Honeycrisp. They have been working on the changeover since 2002.

“We are strong proponents of grafting, at least in our orchard,” says Andrew, adding grafting has not been an issue as far as growth.

He estimates the grafting has been more than 90 per cent successful and the cost has been “pretty minimal.”

He converted his first one-hectare block of Macintosh and Idared in 2002 after a few years of dismal fresh market and processing sales forced him to sell his apples for juice.

Three years after the conversion, Parker began picking in the new block. The fruit quality has been good and he expects about 120 bins this year from the grafted varieties.

In 2006, the Parkers continued their conversion project, grafting a 1988 planting of Macintosh and Idared on M111 rootstock to Honeycrisp and Gala. Andrew admits it has been a challenge to get this block of Honeycrisp to grow into vigorous trees due to light soils. To combat this, the pair irrigates and removes some fruit from the Honeycrisp trees before harvest, while leaving fruit hanging on the hardier Gala.

Andrew harrows his rows to promote tree growth and suppress weeds. He also utilizes an overhead irrigation system, which also doubles as a frost control system on the operation’s low-lying land. “We lost a couple of crops in the early 1980s because of frost,” he recalls.

The Parkers thin their trees using Sevin and, for the first time this season, used the new thinner Maxcel on their 2006 Honeycrisp block.

The couple has found Honeycrisp easy to grow and prune. “We now prune them just like Macintosh,” says Andrew. “It has been a low-maintenance orchard for us.”

Birchleigh Farms

Rockland, Nova Scotia’s Birchleigh Farms has 93 acres of apple orchard and owner Waldo Walsh is busy replanting the operation’s oldest blocks. He recently pruned one block of Honeycrisp, planted on M106 rootstock, using extensive heading cuts followed by large limb removal. In 2007, Walsh harvested 26 bins per acre from this block with a 91 per cent pack out of fruit and he is pleased with the crop performance of the M106 rootstock.

Charles Embree, a research scientist with Agriculture and Agri-Food Canada, believes Honeycrisp does well on M106, although Larry Lutz of Scotia Gold, feels M106 might have phytopthera problems.

At one trial replant site in Walsh’s orchard, it was demonstrated that deep ripping followed by an application of composted hog manure provided the best replanting results, explained Agra Point tree specialist Bill Craig.

Go East

Several years ago, British Columbia native Al Fisher, convinced that Nova Scotia was the best place to grow Honeycrisp apples, bought an orchard near Windermere, N.S.

According to Larry Lutz, Fisher began his extensive replanting in 2006 by deep ripping with a bulldozer, followed by fumigation in blocks that were plotted with geometrical precision using a GPS system.

His replanted blocks use a trellis system, familiar to B.C. apple farmers, involving wooden poles that support the trellis wires, a cheaper to metal conduit. Fisher also built an eight-foot-high deer fence around his orchard.

In 2007, Fisher planted an additional 10 acres of Honeycrisp in four rows on M26 rootstock, accompanied by two rows of Ambrosia on M9 rootstock.

This past spring, Fisher planted 15 more acres, predominantly in Honeycrisp on M26 rootstock at a spacing of about five-feet between trees and a row spacing of 15 feet.

Craig says Fisher plans to ultimately to have about 160 acres of new plantings, with many of those young trees originating from his B.C. nursery, where he is also an organic cherry grower.

Fisher lost a few trees in his 2006 planting due to rodents girdling the tree trunks. The tree rows had been mulched using hay, which provided good cover for the rodents and a perfect environment for collar rot on the M26 rootstock.

van Meekeren Farms

Collar rot also confronted the van Meekeren brothers of van Meekeren Farms near Lakeville, N.S. The rot struck following the operation’s 2003 planting of Gala on M9 rootstock in an orchard that has a heavy soil and is not well drained in its lowest parts.

As a result, during the farm’s subsequent planting in 2007, the brothers placed their new trees on a berm or hilled them.

Fire blight remains the operation’s big management issue, explains Stephen van Meekeren. Despite two years of trials with organic controls – Bloomtime Biological FD and BlightBan C9-1 – in the orchard, the products did not work adequately and so the brothers had to intervene with streptomycin.

Print this page