Features

Fruit

Production

Mechanical blossom thinning of Ontario peach trees

November 18, 2013 By Kendra Sauerteig and Dr. John A. Cline

Mechanical string thinner used to remove flowers from peach trees.

Mechanical string thinner used to remove flowers from peach trees. The Ontario peach industry produces an annual farm gate value of $27 million (Statistics Canada, 2012), but crop load management remains critical for profitability, due to over-cropping. Hand thinning of peaches is common 40 to 50 days after full bloom in order to increase fruit size, but this process is labour intensive and expensive. A two-year study was conducted beginning in 2010 to evaluate mechanical blossom thinning (MBT) of peaches using a string-thinning device, and to determine the effect on crop load, yield, and fruit quality.

Experiment

This experiment was conducted in 2010 and 2011 using seven-year-old Allstar/Bailey peach trees in a commercial orchard (1,121 trees·ha-1) in Virgil, Ont., which were 3.7 m tall and 1.7 m wide. The six treatments were applied at 80 to 90 per cent full bloom and consisted of: 1) MBT at a rate of 180 rpm; 2) MBT at a rate of 210 rpm; 3) MBT at a rate of 240 rpm; 4) HBT simulating the 180 rpm treatment (HBT low); 5) HBT simulating the 210 rpm treatment (HBT medium); 6) HBT simulating the 240 rpm treatment (HBT high); and in 2011, 7) a hand-thinned control treatment, was added. Hand blossom thinning treatments simulated MBT, to assess mechanical damage caused by the rotating strings. The mechanical string thinner (Darwin 300, Fruit-Tec, Deggenhausertal, Germany, available through N.M. Bartlett, Beamsville, Ont.) was mounted to the front of a tractor and consisted of a 3.0 m-tall rotating spindle

|

After June drop, trees were hand thinned and time required to thin was recorded. This was then extrapolated to hours per hectare (h·ha-1) based on orchard tree density. At harvest, the total number and weight of fruit harvested per tree was recorded, as well as the number and weight of naturally dropped fruit. Fruit firmness and soluble solids concentration were measured on a subsample of unblemished fruit. Fruit were also graded, and due to a price incentive for growers, are presented as the percentage of fruit >70 mm.

Results

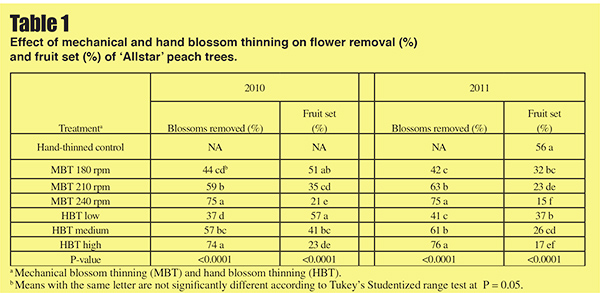

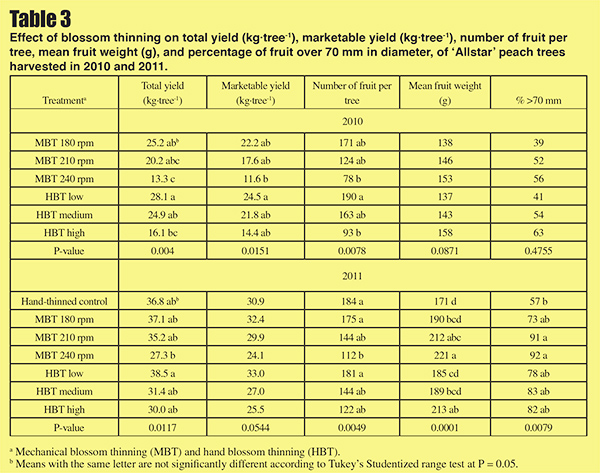

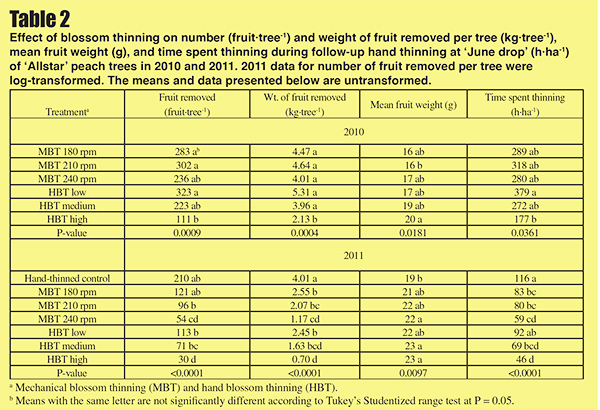

In both years the two methods of thinning were similarly efficacious in removing blossoms (Table 1). In 2010, fruit set decreased linearly with increasing MBT and HBT, while in 2011, fruit set for the hand-thinned control treatment was higher than all other treatments. In 2010, only the HBT high treatment required significantly less time to hand thin at “June drop” compared to all other treatments (Table 2). In 2011 the control and HBT low treatments required the greatest amount of time for hand thinning, while the HBT high treatment again required less hand thinning.

|

Total yield was affected by treatments in both years, and there was a general trend of decreasing yield with increasing thinning rate (Table 3). In 2010, marketable yield decreased linearly with increasing rates of thinning, while in 2011 marketable yield did not differ across treatments. In both years, there was a linear reduction in the number of fruit harvested per tree with increasing rates of thinning. In 2010 mean fruit weight was unaffected by treatment, whereas in 2011 mean fruit weight increased with increasing magnitude of thinning. In 2010, there was no effect of treatment on percentage of fruit in an incentive size category (> 70 mm), but in 2011 the MBT 210 rpm and 240 rpm treatments yielded significantly more fruit in the incentive category. In both years, fruit firmness and soluble solids concentration were unaffected by treatments (data not shown).

Discussion

Approximately 50 per cent of peach blossoms need to be removed to achieve a commercial crop (Marini and Reighard, 2008). Flower removal rates in this study were comparable with other work (Baugher et al. 2010b; Schupp et al. (2008), but in some cases were higher than other reports (Baugher et al., 2010a), perhaps due to the suitability of the orchard for mechanical blossom thinning. Growers should consider their orchard management before using a mechanical thinning device, as other research has found that results can be variable if the canopy is poorly suited for thinning with the device described here (Miller et al., 2011; Schupp et al., 2008).

Early in the growing season, developing fruitlets are competing for limited carbohydrate reserves, therefore thinning early will help allocate more reserves to fewer fruit, thereby improving fruit size (Marini and Reighard, 2008). In 2011 MBT and HBT reduced the amount of follow-up hand thinning after “June drop” by 33-57 h·ha-1 and 24-70 h·ha-1, respectively (Table 2). Other studies have reported time savings as well (Baugher et al., 2010a; Baugher et al., 2010b), where others have proved more variable (Miller et al., 2011; Baugher et al., 2009).

|

In this experiment, there was no significant treatment effect on marketable yield, indicating a compensatory effect of reduced fruit number by increased fruit weight among thinned trees. Other studies have observed improvements in marketable yield (Baugher et al., 2009), while others have proved variable (Miller et al., 2011). With thinning it is important to improve fruit size, but not forfeit economic yield (Marini and Reighard, 2008). In this study there also were no significant treatment effects on fruit firmness or soluble solids concentration (data not shown), which may have been due to the fact that peaches were harvested based on maturity.

Prior to the widespread adoption of mechanical blossom thinning there are several issues that must be addressed. Most importantly, trees must be managed properly to provide adequate access of strings to the tree canopy (Marini and Reighard, 2008). In less suitable orchards compared to the one used in this study, follow-up thinning may be necessary to mitigate inconsistent thinning (Baugher et al., 1991). Another important concern for growers is the risk of frost (Baugher et al., 1991), which could further decrease crop load. One final area of interest that warrants more investigation in Ontario is the timing of mechanical blossom thinning (Costa and Vizzotto, 2000; Schupp et al., 2008).

Overall, mechanical blossom thinning might be approached as a two-part strategy to reduce the amount of hand thinning needed after June drop. Since concern exists of over-thinning due to the higher probability of frost at or shortly following bloom, partial removal of the crop load could be achieved by mechanical blossom thinning with the intention of follow-up hand thinning to reach the targeted final crop load after set has been determined (Myers et al., 2002).

Conclusions

Peach trees can overset, and to solve this problem growers will adjust crop load by hand, the universal thinning strategy (Myers et al., 2002) and by chemical means (Coneva and Cline, 2006; Greene et al., 2001; Osborne et al., 2006), although results have been inconsistent (Marini and Reighard, 2008). In this article we propose mechanical blossom thinning as an alternative, but more research is needed in order to fully understand its effects in Ontario orchards and in order to adequately advise growers (Marini and Reighard, 2008).

We gratefully acknowledge George Lepp for the use of his orchard, as well as the technical assistance of Debbie Norton, University of Guelph.

Kendra Sauerteig and Dr. John A. Cline are with the University of Guelph.

Print this page