Features

Production

Research

Extending storage time under a tent

time under a tent

April 15, 2008 By Dan Wooley

A joint research project

between a Nova Scotia highbush blueberry grower and Agriculture and

Agri-Food Canada’s Atlantic Food and Horticulture Research Centre has

created new technology to extend the storage life of fruit.

A joint research project between a Nova Scotia highbush blueberry grower and Agriculture and Agri-Food Canada’s Atlantic Food and Horticulture Research Centre has created new technology to extend the storage life of fruit.

In the mid-1990s, Nova Agri Inc. chief executive officer Earl Kidston was seeking ways to increase the shelf life of his blueberries in a bid to capture the high prices of end-of-season markets. Earl and his brother, Bobby, had planted late-season blueberries to exploit a market niche. From late September to early November, the North American supply of highbush blueberries contracts after the U.S. harvest. Being in the Annapolis Valley, the brothers’ crop would be last to market and they desired even more market competitiveness through a controlled atmosphere storage technology to enable them to ship to the New England market four to eight weeks later than U.S. producers.

But how could they do it? Earl decided to visit the AFHRC in nearby Kentville in search of an answer.

Dr Charles Forney, a post-harvest physiologist at AFHRC, decided to work with the Kidstons. The key to the brothers’ problem was controlling the respiration of the blueberries, which continues following harvest, he explained.

The team decided that by placing the blueberries on pallets and then covering them with tents made of a thick, impermeable, polymer fabric into which carbon dioxide could be injected, the berries respiration rate and other metabolic processes could be slowed. Combine this with rapid cooling and the quality and shelf life of the fruit increases.

High levels of CO2 in the storage will control decay and botrytis, explained Forney, and he recommends maintaining CO2 “at a beneficial level” of 10 per cent within the controlled atmosphere (CA) tents. They can be continually monitored to keep a constant CO2 level by either injecting the CO2 or by flushing with compressed air.

The principal objective of a CA tent for blueberries is to slow decay, but they can also control ripening and softening in apples. “We are interested in the sugars and acids in the fruit and the flavour volatiles, as well as the textural changes in the fruit during controlled atmosphere storage,” said Forney.

|

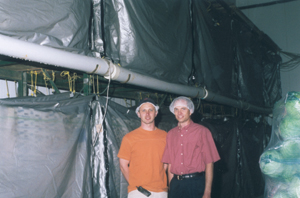

| Darrell Sweet (left), Nova Agri engineer, and Dr. Charles Forney, post-harvest plant physiologist at AAFC Kentville, stand next to controlled atmosphere fruit storage tents developed under a collaborative agreement between Nova Agri Inc. and the AAFC research centre. Photo by Dan Woolley. |

Back in the lab at AFHRC, Forney’s research colleagues are using liquid chromatography to analyze the harvested blueberries’ sugars and acids. They are also performing olfactory analysis by machine and using the human nose to measure the volatile compounds emitted by the berries that contribute to their flavour characteristics.

Forney has also initiated research into transporting fruit under CA conditions “to better understand the respiration of the berry and how to maintain controlled atmosphere during shipping in containers by truck and by ship.” His research is also looking at temperature management as a big factor in CA storages and berry ripening in the field to ascertain the optimum harvest time.

Besides the Kidston brothers, B.C. grower Harvey Krause, general manager of South Alder Farms, has also been collaborating with Forney and his AAFC researchers. While these growers may get a head start on new technology, their collaboration will also give Forney’s research team a fruit supply for analysis and on-site research, enabling them “to see how our research fits into a commercial operation to help keep us relevant,” he said.

Without the federal government’s AFHRC involvement, Darrell Sweet, Nova Agri’s agricultural engineer, feels the company would not have constructed a CA storage facility in 2001. The facility also stores apples for Apple Valley, a maker of apple pies and apple crisp at Cold Brook, near Kentville.

Sweet says Nova Agri is also examining CA storage for other berry crops, including currants, raspberries and blackberries. Cherries are not a feasible storage fruit because the local Annapolis Valley harvest is not large enough.

A properly managed CA storage works very well, he says, “but there is a lot of risk in such a perishable commodity. It can easily turn to garbage.”

Sweet says poor monitoring of the fruit’s quality before it enters storage can result in a $5,000 pallet of fresh fruit turning “into something that is only worth $500 that has to be sent to be frozen” within one week.

Successful CA storage depends upon careful examination of the fruit before it enters the storage and careful monitoring of it after it is stored, said Sweet, adding that different fruit varieties can all be stored in the same storage at the same temperature, but in different tents with their own particular CO2 level.

Print this page