Features

Fruit

Production

Potato and onion sprout control goes eco-friendly

December 2, 2009 By Lukie Pieterse

A British potato and onion storage system has been hailed as “the greatest breakthrough in the seed potato sector” by judges at the PotatoEurope 2009 Conference and Trade Show in the Netherlands in September.

A British potato and onion storage system has been hailed as “the greatest breakthrough in the seed potato sector” by judges at the PotatoEurope 2009 Conference and Trade Show in the Netherlands in September.

The Restrain Generator, described as a natural anti-sprouting system, won the prestigious PotatoEurope 2009 Innovation Award in the face of stiff opposition.

“This product is truly a breakthrough,” the judges noted. “It is very innovative: a natural and environmentally-friendly, anti-sprouting control system is very necessary and this novel technology is welcomed by the industry; it is something the entire potato sector has been waiting for.”

|

|

|||

| The Restrain Generator produces low levels of natural ethylene gas during product storage to help prevent potatoes and onions from sprouting.

|

||||

|

||||

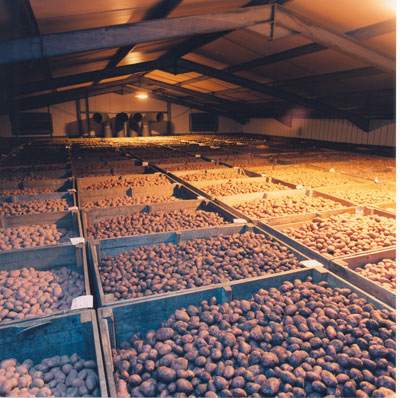

| A new potato and onion storage treatment system from Britain could help with sprouting issues in bulk, box or bag storages. (Submitted photos) |

||||

Restrain is a patented system that uses ethylene gas as a natural sprouting inhibitor in potato and onion storage facilities. The system can be employed in storages where product is stored in bulk, as well as in boxes or bags. The Restrain technology, originally developed by Greenvale AP and ICA Equipment & Instruments in the U.K., has been put to use commercially for more than five years in Britain and has been exported to several countries in Europe, North Africa and the U.S. The Restrain Generator produces low levels of the natural ethylene gas during the duration of product storage to prevent potatoes and onions from sprouting, while leaving no harmful chemical residues on the product after treatment.

Storage managers find that Restrain is very easy to use: there is no need to modify the store and the ethylene generators require only a standard single-phase 13-amp supply – it delivers a “plug and play” solution that can be installed in five minutes. The slow introduction of ethylene into the storage facility is fully automated in the Restrain Generator controls. Restrain Company also introduced a system that is compatible with CA (controlled atmosphere) storage and maleic hydrazide (MH) treatment for onions.

In physiological terms, the natural ethylene gas suppresses cell elongation in potato tubers, which results in eventual sprout control. What happens is in effect a natural and temporary blockage of sprouting due to the ethylene concentration in the storage facility. No chemicals are added when the Restrain system is employed in a storage facility. Technically speaking, the Restrain Generator is factory-preset to maintain a specific required level of ethylene concentration in the storage facility. The ethylene gas is produced from pure ethanol (alcohol) inside the Restrain Generator using a heated catalyst. The Restrain Generator converts ethanol (C2H5OH) via a catalyst into ethylene gas (C2H4) with water as a byproduct.

The specific ethylene levels or concentrations required during the storage are controlled by the Restrain Sensor. This sensor is placed in the air flow on top of the potatoes and signals to the generator if and when it requires more ethylene gas – which is then released by the Generator. The Restrain Company invested in detailed research projects during the course of several years to finally reach a scientifically sound system, which includes know-how as to the specific ethylene levels needed for the system to successfully prevent sprouting.

As a rule the Restrain Company finds that most storage facilities need not be modified or adjusted for successful use of the Restrain system. It is important though that the storage facility is not too “leaky.” If the store is too open and outside air can enter without much control by the storage manager, it is hard to maintain the required minimum levels of ethylene gas during the storage period. The fundamental concept of success with Restrain is to maintain specific levels of ethylene gas over a prolonged time during storage. If these levels are not maintained, the anti-sprouting results will be negative.

In some European countries the Restrain system is now also employed in onion storage facilities to prevent sprouting in store. Some onion packers are reportedly using it in combination with maleic hydrazide (MH) to extend the storage season. The larger onion producers in the U.K. report that ethylene offers management flexibility not previously available. It is not possible to be certain which onions are best for long-term storage until after they are harvested and cured for a period of time in storage. As a result, MH is in most cases applied to the greatest part of a growing onion crop even though not all of the crop will eventually be marketed early from storage. Those onions marketed early need not have been treated with MH. The Restrain ethylene system allows growers to postpone the decision about sprout suppression until the onions are safely stored and cured, and long-term storage lots are identified. Only then is the Restrain system activated.

Late last year Restrain was approved for the storage of organic potatoes and onions. The organic approval applies throughout Europe and was welcomed by Restrain Company’s U.K. manager James Thorburn. “Being a natural, chemical-free system, Restrain is a perfect match for organic producers,” he said. “The approval means organic potato and onion growers can use Restrain to extend their storage time, allowing them to supply the higher value, late-season market. Potentially, it represents a major business boost for organic growers.”

Research trials with the Restrain system were initiated in Canada last year and are ongoing. A spokesman for the company said further details will be made available once these trials have been thoroughly studied and final conclusions are reached.

For more information visit the Restrain website at www.restrain.eu.com.

Print this page