Features

Production

Research

P.E.I. bale processor gaining popularity in horticulture

gaining popularity in horticulture

April 18, 2008 By Marg Land

When Paul Fox of Double R

Manufacturing first started developing a more flexible and portable

bale processor for the livestock market, he had no idea it would find a

following in Canada’s strawberry fields.

|

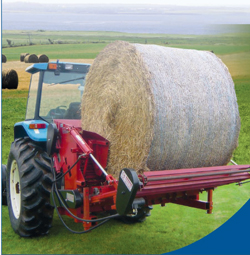

| The BeddingPro designed by Double R Manufactur-ing, is gaining popularity in horticulture circles despite being designed for livestock use. Contributed photo |

When Paul Fox of Double R Manufacturing first started developing a more flexible and portable bale processor for the livestock market, he had no idea it would find a following in Canada’s strawberry fields.

“I wasn’t aiming for the strawberry market,” explained the company president, recalling the day a P.E.I. strawberry grower entered his shop, raving about how well the BeddingPro® worked at spreading straw mulch in his berry fields. “I was scratching my head, trying to figure out what this guy was talking about.”

Now, the Crapaud, P.E.I. – based company is looking to expand its market for the bale processor, which conveniently fits onto a rear- or front-mounted three-point-hitch.

The bale processor has developed a following in the Maritimes.

Claude McCardle of P.E.I. purchased his Double R bale processor a few years ago after contracting out his straw spreading to the operator of a large-scale bale processor.

“It didn’t work out very well,” recalled McCardle, who grows about eight acres of strawberries plus raspberries and low-bush blueberries at his farm, called the Berry Patch.

He went on a hunt for a straw spreader that could be powered by his 50 horsepower tractor, and he discovered the Double R model. “That’s the big advantage. I didn’t have a very big tractor and with those big bale busters, you require at least a 90 horsepower tractor.”

McCardle, who’s farm is located just outside of Charlottetown near Mount Stewart, described his bale processor’s coverage as “perfect. It basically unrolls the bale as it was originally baled up. And you can control both the speed of the bale as it rolls out and your forward speed.”

He also is very pleased with the ease of operation of the bale processor. “I can do it myself; no other labour is required.” This is a stark contrast to the amount of labour McCardle used to require when he operated a small square bale processor. “You had to follow the machine. (And) there were two guys sitting there looking at you all the time.”

Ralph Stirling, production manager of Stirling Fruit Farms, had an opportunity to use the Double R machine on his family’s Wolfville, N.S., area operation last year, mulching straw onto the farm’s eight acres of strawberries.

“Of all the ones (bale processors) I’ve tried, this one worked the best,” he said. “Most chop too fine or don’t have even coverage. Sure, it takes a little practice but this one worked great.”

He added the bale processor had a bit of trouble dealing with lower-quality barley straw. “It was hard to get through. You need to have good straw.”

Stirling hopes to purchase a BeddingPro in the near future. For now, the farm spreads all of its mulch manually, hand rolling round bales down the rows and spreading with hay forks.

Fox is hoping to spread the word about his product further afield. Last fall, he travelled to Ontario with his BeddingPro proto-type, providing a field test in a Guelph-area berry field. About 10 to 12 growers from as far away as Ottawa viewed the test, which lasted about two to three hours. By the end, “everyone was happy,” said Fox. “Every grower does something different; a different thickness, a different speed.” Over the course of the test, Fox made adjustments to his bale processor, easily accommodating the demands of the assembled growers.

Fox explained that many growers are impressed with the coverage his bale processor provides. With one round bale equalling approximately the amount of straw found in 18 small square bales, many of the assembled growers explained they can get eight-inches of coverage over 500 feet from 18 small square bales. Using the BeddingPro, Fox achieved an eight-inch coverage over 1,500 feet using one round bale.

“It shreds and fluffs,” he said. “That’s what impresses them the most; the bale goes so much further.”

The BeddingPro is designed to fit on new or existing tractors with a minimum 40 horsepower engine, making it ideal for both large and smaller growers. It is relatively compact with a size of five-and-a-half square feet and has a base weight of 1,000 pounds. Fox explained the small size allows it to work in small spaces with little head room, such as under netting or ginseng shade. The machine is also being designed to keep the dust, often associated with bale processing, to a minimum.

Besides Ontario, the prototype has also undergone some field testing in Nova Scotia, New Brunswick and P.E.I. Based on that feedback, Fox said the company is now working to develop attachments that will handle such things as self-loading, side delivery and a bottom fan delivery. Fox hopes these attachments will allow the shredder to meet the requirements of livestock growers. And for crops like strawberries, blueberries, ginseng and vegetables, the self-loading feature would free up a tractor that would normally be needed to load the shredder. Heavier bales can weigh up to 2,000 pounds and would require a tractor equipped with a pay loader.

With funding help from the Prince Edward Island ADAPT Council (which administers the Canadian Adaptation and Rural Development Fund in the province for Agriculture and Agri-Food Canada), Fox said the company now hopes to bring the device to the point where it is ready to go into commercial production.

Double R Manufacturing currently has two employees, but Fox said if the machine progresses to the point of commercial production, it would mean a significant increase in year-round jobs. “We’re really excited about it and we’re keeping our fingers crossed,” he said.

Print this page