Features

Fruit

Production

Key Technology optical sorting system

October 19, 2009 By Fruit & Vegetable

October 19, 2009 – Key

October 19, 2009 – Key

Technology introduced its first optical sorting system for whole potatoes.

October 19, 2009 – Key

Technology introduced its first optical sorting system for whole potatoes.

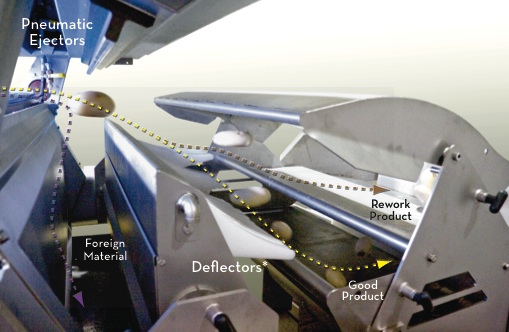

Optyx WPS for whole

potatoes achieves a three-way sort using a combination of air ejectors to

remove foreign material and a deflector system to separate potatoes for rework

from good potatoes.

|

|

Optyx WPS can sort peeled

and peel-on product, differentiating peel from scab, bruise, rot, and green

defects. Using cameras, Optyx WPS recognizes colour, size, and shape to remove

potatoes needing re-work based on the presence of peel, scab, or gross defects,

as well as potatoes that fail to meet user-defined standards for length, width,

or shape. Using a combination of

Raptor laser technology with high resolution line scan cameras, Optyx WPS

reliably detects and removes foreign material based on the structural

properties of the material, as well as visible colour.

As the product passes

through the sorter, it is scanned by cameras without leaving the conveyor belt.

Product is then launched off the end of the Optyx WPS belt for in-air viewing

by the Raptor laser sensor. Using proprietary image processing technology, the

sorter analyzes the images, comparing each object to previously defined

accept/reject standards. When foreign material is identified, the system

activates the close-coupled high-speed air ejector system, which is made up of

a series of high-flow valves spaced 0.25 inches (6 mm) apart that span the

width of the system. While the foreign material is still air-borne, the air

jets pinpoint the object to reject and precisely remove it from the product

stream via the FM chute.

|

|

Optyx 6000 WPS handles up

to 100,000 lb. (45 metric tons) of whole potatoes per hour. By sorting potatoes

prior to cutting, processors protect the cutters’ knives from damage caused by

foreign material, which maximizes product quality and improves production line

up time. By automating the sort, processors reduce labor costs. By achieving a

three-way sort with Key’s powerful G6 digital image processing capabilities,

potato processors can define their sort criteria to increase yields and speed

payback.

Print this page