Features

Production

Research

A spa treatment for fruits and vegetables

December 2, 2009 By Dan Woolley

Everyone deserves a bit of pampering at the spa. And it seems fruits and vegetables can benefit from the experience as well.

Everyone deserves a bit of pampering at the spa. And it seems fruits and vegetables can benefit from the experience as well.

According to recent research conducted by Agriculture and Agri-Food Canada (AAFC), treating fruits and vegetables to a sauna can improve their colour, flavour and quality while extending their shelf life by more than half.

|

|

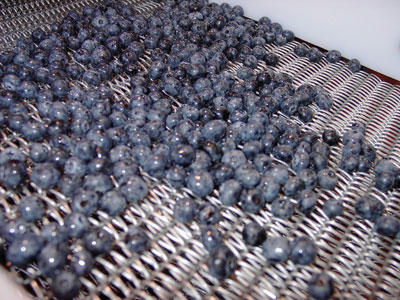

| Blueberries undergo their “spa” treatment using Low Temperature Thermal Treatment, or LT3 for short. |

|

|

|

| ABCO Industries is hoping to take the LT3 research and commercialize the machine. The company currently has one unit being field-tested. (Submitted photos) |

In light of this discovery, researchers at AAFC’s Atlantic Food and Horticulture Research Centre in Kentville, N.S., have developed a processing machine called LT3, which stands for Low Temperature Thermal Treatment.

The LT3 works by administering moist air heated to a carefully controlled temperature approaching 50 degrees Celsius. The steam is applied to the produce and reportedly helps to diminish micro-organisms on the surface that can reduce produce shelf life. Longer shelf life could bring big savings to consumers and retailers: Statistics Canada estimates that nearly 50 per cent of produce purchased is discarded by stores, customers and restaurants, mainly due to spoilage.

The process also helps to activate chemical processes in the fruits and vegetables to help improve colour, flavour and quality, and the machine’s steam doesn’t leach the nutrients out of the produce, researchers say.

A food processing and quality team, led by research scientists Dr. Bob Stark and Katherine Sanford, developed the LT3 machine. They claim the machine’s treatment is more efficient than the hot water treatment currently applied to fruits and vegetables.

The team’s research began after a local grower reported he was having difficulty keeping the colour in his fresh-cut cabbage, explained Sanford.

The researchers worked from previous research by AAFC’s Pacific Agriculture Research Centre in Summerland, B.C., that examined the effects of dipping produce in warm water, plus more than 30 years of work by Dr. Stark – in collaboration with ABCO Industries of Lunenburg, N.S. – developing a series of energy-efficient steam blanchers for the food processing industry. So it made sense to look at steam-heated air to treat fruits and vegetables, Sanford said.

“We had to determine the optimum temperature and exposure time for each fruit and vegetable,” she said.

AAFC’s food processing and quality team joined forces again with ABCO, who conducted the engineering and built the prototype LT3 machinery. The team had to establish two principal benchmarks:

| • | Did the LT3 treated commodity remain safe for human consumption during its shelf life? |

| • | Did the LT3 treated product have consumer appeal? |

The machine has been tested on a wide range of fruits and vegetables, as well as almonds.

“Our team worked with microbiologist Tim Hughes who monitored all the safety aspects as they related to the shelf life of the treated food,” said Sanford.

The research phase was completed before the treated food was sent for human testing, she explained. It was first evaluated by a trained panel of sensory experts who looked at how the technology affected the colour, tastes, texture and flavour of the LT3-treated food, said Sanford, adding that it was then referred to a larger panel of consumers, who indicated what appealed to them about the LT3-treated product.

ABCO, which makes custom-engineered thermal treatment machinery for the food industry, is hoping to take the LT3 research and commercialize it as the company did with Dr. Stark’s blanchers, which are now sold all over the world. Graham Gerhardt, manager of the food machinery group at ABCO, says his company currently has one LT3 unit being field-tested “to prove the concept works as well in the plant as it does in the lab.”

One Nova Scotia company is seriously looking at the LT3 technology to increase the shelf life of its fresh cut produce, while enhancing food safety for its customers, said Gerhardt, adding other companies, including international firms, have also expressed interest in the LT3.

The LT3 can also serve as a commercial cooker as researchers have successfully used it to cook small potatoes for the potato salad market.

Print this page